01.

Reduce costs

Moving goods around large industrial sites can be costly. Starship robots integrate easily into your existing processes, delivering autonomously without the need for additional personnel.

Our robots boost productivity on industrial sites, moving samples, spare parts and internal mail.

Our robots safely operate at L4 autonomy, monitored 24/7.

Our battery-powered robots help you reduce onsite emissions.

Starship robots are ready to reduce your operational costs, minimise your carbon footprint and boost productivity onsite…

Starship robots can move a wide variety of goods around your facility – such as spare parts, office supplies and internal mail – ensuring fast and reliable delivery.

From an urgent chemical sample to a temperature-sensitive item requiring special care, our robots are up to the task.

Starship’s robots operate at Level 4 autonomy, safely making 150,000 crossings around the world, every day.

The robots are monitored by a human who can assist at any time. This way, pop-up construction sites and other obstacles can be avoided, ensuring minimal disruption.

Our cutting-edge technology guarantees reliable, consistent deliveries, even in changing environments.

Starship robots are equipped with a sensor suite for 360-degree awareness. This system includes cameras, time-of-flight (TOF), radar and an integrated alarm system.

High-visibility features such as LEDs, a flag and reflective markers ensure the robot remains highly visible, even in low-light conditions.

For security, the robot’s compartment remains locked in transit, and can only be opened by the designated recipient. This way, Starship deliveries are always safe and secure.

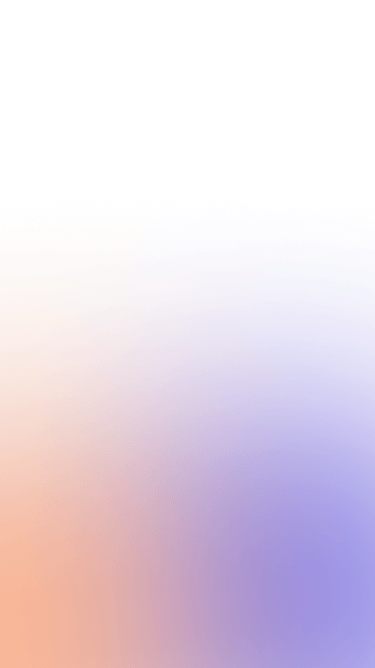

Before the first delivery, we map your industrial premises. Loading points are defined and hazardous areas are excluded from robot route-planning.

All employees involved are personally trained by us.

We familiarise you with the robot and show you how to make and receive deliveries.

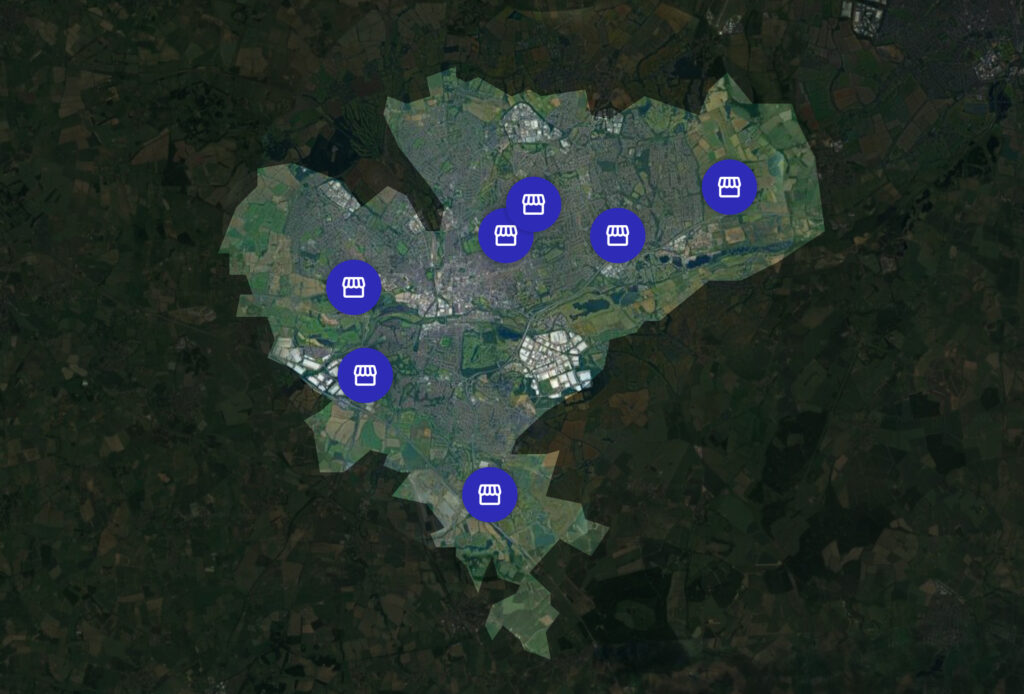

We work via a browser-based platform, so the robots can be loaded and unloaded from a computer, tablet, laptop and mobile phone.

Deliveries can always be clearly tracked by the recipient and sender.

Our robots can adjust for temporary road closures, such as for pop-up construction work. Our route planning algorithm finds alternative routes in real-time and redirects the robots.

We handle customer service for you. If there are any problems, questions or suggestions from employees, our team is ready to help. During the service period, they can be contacted at a moment’s notice.

There are usually further uses for internal logistics than initially outlined. We help identify this potential and introduce new uses cases for our robots.